Miura began in 1927 manufacturing rice threshing machines that required steam.

It became obvious that there would be a universal need for efficient and reliable steam in other areas. So in 1959, Miura developed the ZP type boiler and the Miura Co., Ltd was born. The innovative compact and efficient design of the Miura boiler was a brilliant answer in a country where all fuel is imported and space is a premium. Since then, Miura has grown to 57% of the domestic once-through boiler market in Japan with factories throughout Southeast Asia, the Americas and our recent facilities in Europe and the Middle East. Today, we produce the most efficient boiler system solutions in the world, from 50 BHP up to 4,500 BHP with a single lead lag controller.

WITH THE PRESS OF A SINGLE BUTTON, MIURA BOILERS PRODUCE STEAM IN FIVE MINUTES OR LESS.

Would you buy a car that needs to idle all night long or warm up for 90 minutes before you can drive it? Of course not. So why put up with that for your boiler? There’s no-warm up necessary. In five minutes or less from start-up, you’ve got steam to run your processes, heat your facility or whatever you need it for, when you need it. Miura’s boilers feature fast starts that track precisely to drastic load swings. With our innovative “MI” (Multiple Installation) system, you can build an on-demand steam plant customized to meet your specific demand requirements. Our MI system provides the flexibility to build to current steam loads within very tight tolerances, and our more efficient boilers are synchronized to give you the steam you need and cycle on and off when you don’t need it.

Miura boilers meet lower NOx standards, reduce maintenance and monitoring needs, and reduce space requirements. And they do it with the most real-world, in-service efficiency possible, saving you up to 20% on fuel costs.

SMALLER IS BETTER

Miura’s unique, compact modular design utilizes a low-volume pressure vessel, offering output capacities comparable to much larger traditional, outdated boilers. The resulting smaller boiler footprint provides design flexibility, reduced construction costs and more options with existing spaces. Miura boilers eliminate tube pull-space and door-swing space requirements typical of conventional designs. This allows configuration of the boiler room for double the output of an existing boiler plant or reduction of its size by over fifty percent. And a Miura boiler system is so flexible, you can have multiple boilers working on the same system in separate installations or install Miura boilers at the point-of-use in order to eliminate energy loss through line transmission.

Miura’s unique, compact modular design utilizes a low-volume pressure vessel, offering output capacities comparable to much larger traditional, outdated boilers. The resulting smaller boiler footprint provides design flexibility, reduced construction costs and more options with existing spaces. Miura boilers eliminate tube pull-space and door-swing space requirements typical of conventional designs. This allows configuration of the boiler room for double the output of an existing boiler plant or reduction of its size by over fifty percent. And a Miura boiler system is so flexible, you can have multiple boilers working on the same system in separate installations or install Miura boilers at the point-of-use in order to eliminate energy loss through line transmission.

Read more about modularity and why size matters.

MIURA SAVINGS SOLUTIONS

Miura’s low water volume design results in optimal heat transfer with fuel-to-steam efficiencies of 85% +/- at all load conditions, which in turn, can save hundreds of thousands of dollars per year.

Read more about Miura’s saving solutions.

WE MAKE MAINTENANCE EASY AND FAST

A well-maintained Miura boiler provides the highest efficiency throughout the life of the system and protects this important investment. It’s an essential part of keeping your Miura boiler running like the day you bought it. And with a 3-hour shutdown for routine inspections, you don’t have to lose a whole day or shut the whole plant down. Just shut down one modular boiler and keep the others up and running. From water analysis, to our MOM online support systems, to overall efficiency, our Miura boiler maintenance program ensures that you’ll save down time while saving energy costs. Plus, most parts are covered free, and emergency service is available should you need it.

Learn more about Miura maintenance.

A WARRANTY YOU CAN COUNT ON, AND THE ONLY MANUFACTURER WHO GUARANTEES IT

Miura is known around the world for our dedication to quality and our ongoing drive for excellence. Our products are supported by the best engineering technology in the industry and every Miura boiler is backed by a warranty you can count on. By choosing Miura’s maintenance & inspection program, you’ll be making a wise decision assuring worry-free boiler operation.

Our guarantee covers most parts and labor costs, as well as the industry’s only Pressure Vessel Guarantee (with the MMC/MMRC program only) against corrosion. By selecting our maintenance & inspection program, you enlist Miura’s expert stewardship over the long-term reliable and efficient operation of your boilers.

Download a printable version of our warranty.

SAFETY SOLUTIONS

With more than 200,000 units in operation world-wide, Miura has never had a pressure vessel explosion. Ever. Miura boilers are intrinsically safer by design. With low water content combined with the unique boiler geometry, catastrophic vessel failure is practically impossible. Miura boilers also have numerous safeguards beyond primary vessel safety to ensure not only safe operations, but also high efficiency and reliable operation.

Victory Energy was started by John Viskup, President and CEO with a single minded mission to provide customers with the best Boilers, Burners, HRSG’s, Heat Transfer Solutions and Services. Every action across every day that the company makes has been based on paying off on this core promise. The company has disrupted the market in real and substantive ways that are delivering significant value for the customer. We’re all in with everything we do, providing the best boilers engineered and manufactured by the best people.

Increasingly, customers are seeking out Victory Energy as the company of choice for all their steam requirements. We’re represented by the best independent sales representatives across North America and increasingly across the globe as the footprint for the company expands worldwide.

We’re committed to continually investing in our facilities having undergone an extensive plant expansion in our Collinsville operation and adding a game changing steam test facility to start-up all of our products prior to shipment. Another example for how Victory Energy is distancing away from competition.

Paying off on our concept to completion point of difference is a key driver of future growth. Our product portfolio reflects a complete offering with the addition of VISION burners and a full line of FRONTIER firetube boilers.

WETBACK FIRETUBE BOILERS

Victory Energy has long been a trusted name in the manufacturing of wetback firetube boilers for use in demanding applications. Available in 2-pass, 3-pass and 4-pass configurations. They’re engineered to perform in virtually every industry setting.

2, 3, and 4-pass designs

Up to 2,500 HP

Up to 86,250 PPH

Heavy-duty skids

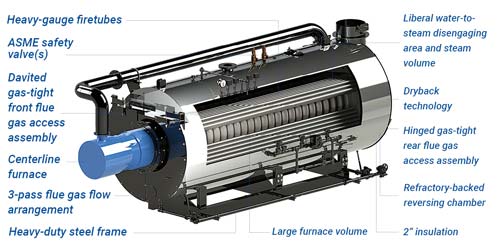

DRYBACK FIRETUBE BOILERS

Victory Energy manufactures a comprehensive line of dryback firetube boilers that are available in a multiple of horsepower range configurations from 50 HP to 2,500 HP designs.

2 and 3-pass designs

Center fired design

Stainless steel jacket

Advanced refractory technology

50 HP to 2,500 HP

862 PPH to 34,500 PPH

WASTE HEAT FIRETUBE

Victory Energy offers a full range of firetube waste heat recovery boiler systems to meet the wide cross section of waste heat project requirements – from sub-critical on through to demanding industry applications.

WE GO THE EXTRA DEGREE – FROM CONCEPT TO COMPLETION.

We produce the world’s best industrial steam boilers, burners and heat recovery products. We’re the game changers in a mature industry. Our concept to completion promise redefines everything.

We pursue innovative industrial steam solutions. Delivered through advanced manufacturing facilities and supported by unmatched aftermarket support. We’re with you every step of the way from bid to commissioning and product start-up. Count on Victory Energy from concept to completion.

EXACTING & THOROUGH

What we term process acuity is evident and resides in every industrial steam product. Perfection is the standard to which we hold ourselves. Our processes are among the most advanced in the industry. Lean thinking found throughout the plant eliminates waste and reduces lead times.

Our engineering experience runs deep with broad backgrounds of specialties. We apply these talents to all our products including, industrial boilers, firetube boilers, HRSG – gas turbine heat recovery solutions, waste heat boilers, burners, economizers, high temperature, hot water thermal generators.

DELIVERING ON THE PROMISE OF EFFICIENCY AND RELIABILITY.

No company supports its products better than Victory Energy. Everything is designed around your application and project needs. We value your custom requirements. Our people, both company employees, and our valued sales reps work in sync with you throughout the life of the project.

You can count on us for the life of your industrial steam boiler. Our end-market team will ensure that your boiler runs at peak performance. You’ll find us standing with you, through spare parts planning and sourcing, preventative maintenance and routine service.

FIRETUBE BOILERS

From a dedicated manufacturing facility through to producing a full line of wetback and dryback firetube boilers, Victory Energy is all in with firetube boilers! Backed by the best-in-class distributors that sell and service our firetube product offering, we’ve made a concerted effort to be the best manufacturer of firetube boilers that create maximum customer value.